| Visitors Now: | |

| Total Visits: | |

| Total Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

Hybrid printing of mechanically and biologically improved constructs for cartilage tissue engineering applications

From

A new tissue printer can print cartilage.

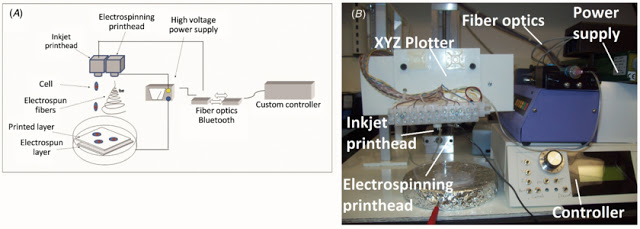

Bioprinting is an emerging technique used to fabricate viable, 3D tissue constructs through the precise deposition of cells and hydrogels in a layer-by-layer fashion. Despite the ability to mimic the native properties of tissue, printed 3D constructs that are composed of naturally-derived biomaterials still lack structural integrity and adequate mechanical properties for use in vivo, thus limiting their development for use in load-bearing tissue engineering applications, such as cartilage. Fabrication of viable constructs using a novel multi-head deposition system provides the ability to combine synthetic polymers, which have higher mechanical strength than natural materials, with the favorable environment for cell growth provided by traditional naturally-derived hydrogels. However, the complexity and high cost associated with constructing the required robotic system hamper the widespread application of this approach. Moreover, the scaffolds fabricated by these robotic systems often lack flexibility, which further restrict their applications. To address these limitations, advanced fabrication techniques are necessary to generate complex constructs with controlled architectures and adequate mechanical properties. In this study, we describe the construction of a hybrid inkjet printing/electrospinning system that can be used to fabricate viable tissues for cartilage tissue engineering applications. Electrospinning of polycaprolactone fibers was alternated with inkjet printing of rabbit elastic chondrocytes suspended in a fibrin–collagen hydrogel in order to fabricate a five-layer tissue construct of 1 mm thickness. The chondrocytes survived within the printed hybrid construct with more than 80% viability one week after printing. In addition, the cells proliferated and maintained their basic biological properties within the printed layered constructs. Furthermore, the fabricated constructs formed cartilage-like tissues both in vitro and in vivo as evidenced by the deposition of type II collagen and glycosaminoglycans. Moreover, the printed hybrid scaffolds demonstrated enhanced mechanical properties compared to printed alginate or fibrin–collagen gels alone. This study demonstrates the feasibility of constructing a hybrid inkjet printing system using off-the-shelf components to produce cartilage constructs with improved biological and mechanical properties.

See more and subscribe to NextBigFuture at 2012-11-23 16:41:57 Source: http://nextbigfuture.com/2012/11/hybrid-printing-of-mechanically-and.html

Source: