| Visitors Now: | |

| Total Visits: | |

| Total Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

Low-cost MEMS Fabrication Technology Using a Replica Molding Technique

From

Kazuma Kurihara (Senior Researcher) and Hideki Takagi (Leader), Large Scale Integration Team, the Research Center for Ubiquitous MEMS and Micro Engineering have developed a microelectromechanical systems (MEMS) device fabrication technology that uses only printing and injection molding. This has been achieved by integrating the microfabrication technology and the MEMS design evaluation technology of AIST. A lighting device has been fabricated by combining the signal processing technology of Design Tech Co., Ltd. (President: Hatsuo Suzuki) with the developed technology.

* A microelectromechanical systems fabrication technology based only on printing and injection molding has been developed.

* Small capital investment and low production costs make it easier to enter MEMS device fabrication business.

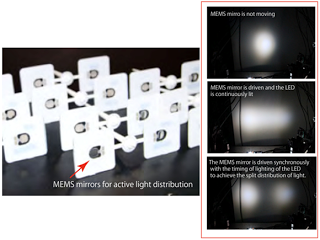

* Use of the technology may help develop new applications of MEMS devices, including in the lighting industry.The developed technology makes it possible to fabricate MEMS devices by using the printing technology that enables the fabrication of large-area devices without a vacuum process and the injection-molding technology that requires small capital investment and enables low production costs. MEMS devices currently produced by using semiconductor manufacturing processes can now be fabricated inexpensively and with a small capital investment. This allows the applications of MEMS devices in fields where MEMS cannot currently be used owing to high production costs and low production volumes. For example, new applications in the lighting industry can be developed by combining active variable light distribution by a MEMS mirror and LED lighting.

MEMS mirrors for active light distribution fabricated by using only printing and injection molding (left), and examples of the resulting light distribution patterns (right)

See more and subscribe to NextBigFuture at 2012-11-21 15:42:36 Source: http://nextbigfuture.com/2012/11/low-cost-mems-fabrication-technology.html

Source: