| Visitors Now: | |

| Total Visits: | |

| Total Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

Time for DNA Manufacturing reduced from weeks to minutes and process for validation of the manufactured DNA structures enabled

From

Eurekalert – Two major barriers to the advancement of DNA nanotechnology beyond the research lab have been knocked down. This emerging technology employs DNA as a programmable building material for self-assembled, nanometer-scale structures. Many practical applications have been envisioned, and researchers recently demonstrated a synthetic membrane channel made from DNA. Until now, however, design processes were hobbled by a lack of structural feedback. Assembly was slow and often of poor quality. Now researchers led by Prof. Hendrik Dietz of the Technische Universitaet Muenchen (TUM) have removed these obstacles.

One barrier holding the field back was an unproven assumption. Researchers were able to design a wide variety of discrete objects and specify exactly how DNA strands should zip together and fold into the desired shapes. They could show that the resulting nanostructures closely matched the designs. Still lacking, though, was the validation of the assumed subnanometer-scale precise positional control. This has been confirmed for the first time through analysis of a test object designed specifically for the purpose. A technical breakthrough based on advances in fundamental understanding, this demonstration has provided a crucial reality check for DNA nanotechnology.

In a separate set of experiments, the researchers discovered that the time it takes to make a batch of complex DNA-based objects can be cut from a week to a matter of minutes, and that the yield can be nearly 100%. They showed for the first time that at a constant temperature, hundreds of DNA strands can fold cooperatively to form an object — correctly, as designed — within minutes. Surprisingly, they say, the process is similar to protein folding, despite significant chemical and structural differences. “Seeing this combination of rapid folding and high yield,” Dietz says, “we have a stronger sense than ever that DNA nanotechnology could lead to a new kind of manufacturing, with a commercial, even industrial future.” And there are immediate benefits, he adds: “Now we don't have to wait a week for feedback on an experimental design, and multi-step assembly processes have suddenly become so much more practical.”

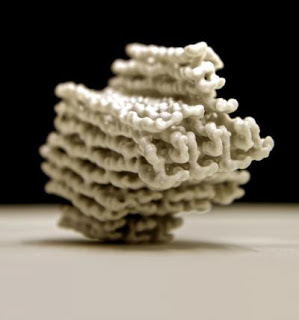

Caption: This 3-D print shows a DNA-based structure designed to test a critical assumption — that such objects could be realized, as designed, with subnanometer precision. This object is a relatively large, three-dimensional DNA-based structure, asymmetrical to help determine the orientation, and incorporating distinctive design motifs. Subnanometer-resolution imaging with low-temperature electron microscopy enabled researchers to map the object — which comprises more than 460,000 atoms — with subnanometer-scale detail. Credit: Dietz Lab, TU Muenchen

Three research papers detail the work

Science – Rapid Folding of DNA into Nanoscale Shapes at Constant Temperature

See more and subscribe to NextBigFuture at 2012-12-13 20:23:02 Source: http://nextbigfuture.com/2012/12/time-for-dna-manufacturing-reduced-from.html

Source: