| Visitors Now: | |

| Total Visits: | |

| Total Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

Threshing wheat

For those of you who were following our wheat-growing experiment last year, you might have wondered how much usable wheat we ended up with. Well, I couldn’t tell you — because we still hadn’t threshed it.

All winter long, most the wheat was stored in a friend’s trailer.

The remaining wheat was triple-wrapped in tarps. We hope it’s okay but we haven’t unwrapped it yet to find out.

Between cold or otherwise bad weather — and no need to rush — we just never got around to threshing anything. But now our friend needs his trailer back, so we have to get that wheat threshed ASAP.

Another reason for our delay in getting the wheat threshed was, quite frankly, we didn’t know how to do it. Oh sure, we knew academically what we needed to do, but book knowledge and actually doing it are vastly different things. But since push had now come to shove (and, not incidentally, the weather was finally moderating), we decided to apply the book knowledge and see where it got us.

First thing we needed was a tarp, as a clean surface for threshing. For some time now, we’ve been collecting old vinyl billboard tarps, which will be used for weed control in the garden.

These tarps are very thick and sturdy (and colorful!). This particular tarp was advertising something for Burger King.

Don backed the trailer onto the edge of the tarp and opened the back.

The wheat was solidly packed in, very dry, with no water or rodent damage. Whew!

But now what? This was the part that had us stumped. Originally we thought we’d lay out a single layer of bundles, cover them with another tarp, then roll a heavy tractor tire back and forth across it to loosen the wheat. These tires weigh upwards of 300 lbs., so that would be a significant amount of weight.

But one look at the wheat — and a few experimental stomps across the bundles — and we knew this wasn’t going to work. The wheat needed agitation, not weight. What now?

While we discussed our options, the chickens descended upon us, having concluded that we had spread a feast solely for their benefit.

Next Don decided to try an experiment: If he stuffed a sheaf of wheat into a clean garbage can and used a weed whacker, would that rattle the wheat loose?

It worked — sorta — but it also ripped the wheat straw to shreds (making it harder to separate from the chaff and kernels), and it also went through an extraordinary amount of weed whack cord. Back to the drawing board.

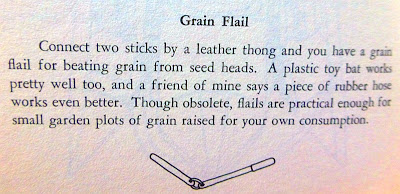

What we needed, of course, was a flail, but we didn’t have one… nor were we sure how to make one. A quick search on the internet revealed lots of ways to make a Medieval weapon called a flail; but a lot less info on the farm implement. However a hasty consultation in our grain-growing bible…

…revealed this gem:

A piece of garden hose! Now that we’ve got. I knew just where a chunk of old garden hose was.

Without further ado, we cut the hose piece where it was already kinked, and gave that a try. We started by holding it in two hands, like an arc, and beating the wheat with that.

However we soon switched to the one-handed version. This allowed us to rest one hand while using the other, and we could swap back and forth. We’ll probably duct-tape these for an easier grip.

And then we started flailing the wheat. The first thing we learned is we had to cut the sheaves (we originally thought we could keep the sheaves tied, but no). Then we learned we had too much wheat spread out on the tarp. It was too thick, and the top wheat cushioned the wheat at the bottom. We needed a thinner layer.

So we pitchforked most of the wheat into a pile at one end of the tarp, and just spread about two bundles at a time. Then we got down on our knees (or sat on a crate) and started whaling at the wheat. The hoses worked beautifully as flails.

When wheat kernels are released, the wheat head starts to look fuzzy or ragged. The head on the left is intact; the head on the right has the wheat kernels beaten out of it.

We beat the wheat until we saw that most of the heads were ragged. Then we forked up a bit of wheat straw, shook it gently, and pitched it to one side.

What was left was a mess of kernals, chaff, beaten wheat heads, straw, etc.

We scooped this up with a snow shovel and a shop broom…

…and poured it into a clean garbage can.

The chickens avoided our little threshing floor, but they took full advantage of the discarded straw.

Once the first sheaves of wheat were threshed, we spread more wheat out and repeated the process. Again. And again. And again. And again. By the end of about three hours, we had all the wheat we had initially pulled out of the trailer, threshed… and we were pooped. And sore.

This was our loot for the afternoon: about forty pounds of mixed wheat berries, chaff, wheat heads, straw, etc. We have a lot of cleaning and winnowing to do, obviously. But this only represents about one-eighth or less of the wheat we have to thresh.

Despite our efforts, though, we found that many of the beaten wheat heads still contained a couple grains of wheat. Hand-harvesting, we’re learning, is massively inefficient next to the fanatical precision of mechanical harvesters or combines.

Out of the original 200 lbs. of wheat we sowed, what was our return? At this point, we have no idea since it’s not all threshed (threshing, we’re realizing, is going to take awhile). Hopefully it was “worth” it, meaning we recouped significantly more than those original 200 lbs we sowed.

One thing’s for durn sure… I appreciate a loaf of bread a lot more than I used to.

2013-03-25 21:51:47

Source: http://www.rural-revolution.com/2013/03/threshing-wheat.html

Source: