| Visitors Now: | |

| Total Visits: | |

| Total Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

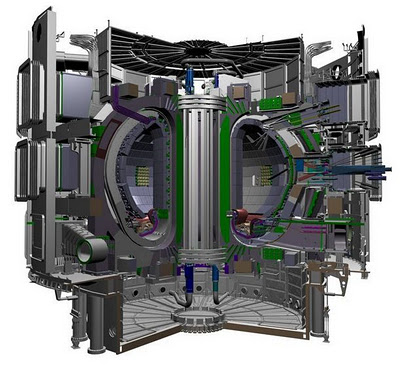

New Nano Material For Thermonuclear Fusion Reactors

The ITER project (under construction) and its successor, DEMO (scheduled for 2035) propose development of fusion reactors that are economically viable. This work depends on, among other things, the development of these new structural materials capable of withstanding damage by irradiation and elevated temperatures resulting from the fusion reaction. The scientific community has begun to develop new reduced – activation material for use in these reactors, but it is still not known if some of them will be viable under such hostile conditions. Along these lines, one of the most important candidates is oxide dispersion-strengthened, reduced-activation ferrite steel, called ODS steels.

The mechanic behavior of the ODS steels depends enormously on their microstructure, which until now has not been rigorously controlled. Until recently, studies on the microstructure of these steels have been on the micrometric scale. However, the nanometric scale is more relevant in understanding the phenomena that occur under irradiation.

The characterization of these materials is carried out using nanometric scale techniques. For example, with a transmission electron microscope, particles can be seen which are added to the material, even the smallest one of a nanometer (one millionth of millimeter). Because of this the following can be studied: if the distribution of the particles is optimum, its chemical composition, or if by changing it, better material is obtained or if interaction of these particles with the defects produced in the material is improved.

This research, funded by the Ministry of Science and Innovation, is focused on the study of oxide nanoparticles which are present in these steels, and the damage caused by radiation of these materials. The analyses carried out up to now show, for example, that the particles have a core-shell type structure consistent in an yttrium(Y) -rich nucleus surrounded by a chrome (Cr)-enriched area.

Contacts and sources:

Universidad Carlos III de Madrid – Oficina de Información Científica

Citation: Analytical characterisation of oxide dispersion strengthened steels for fusion reactors

Authors: de Castro, V. Lozano-Pérez, S. Marquis, E. A Auger, M. A. Leguey, T. Pareja, R.

Source: Material Science and Technology. Volumen: 27 Número: 4 Páginas: 719-723

ISSN: 0267-0836

Read more at Nano Patents and Innovations

Source:

Hot fusion does not work ! They have spent billions trying to get this white elephant to work

But it’s a non starter if they invested that money in cold fusion we would have free energy by now