| Visitors Now: | |

| Total Visits: | |

| Total Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

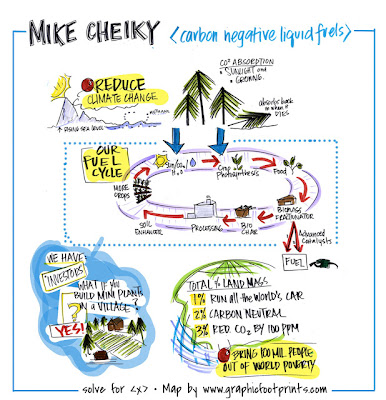

Solve for X – CoolPlanet’s carbon negative liquid fuels

From

What if there was a way to take plant waste (like corn husks) and turn it into bio fuels? What if this also removed carbon from our atmosphere? What if the same process also produced a substance that would help turn deserts back into productive crop land? What if this process could be done on an industrial scale but also could be made self-contained in a small village so that farmers all over the world could get the economic benefits of producing bio fuels with their agri-waste and simultaneously help clean our atmosphere? Too good to be true?

CoolPlanet Energy Systems is developing a revolutionary thermal/mechanical processor which directly inputs raw biomass such as woodchips, crop residue, algae, etc. and produces multiple distinct gas streams for catalytic upgrading to conventional fuel components.

In support of the above biomass fractionator , the company is also developing a range of simple one-step catalytic conversion processes which mate with the fractionator's output gas streams to produce useful products such as eBTX (high octane gasoline), synthetic diesel and proprietary ultra-high crop yield super fuels.

CoolPlanet Energy Systems plans to package its proprietary biomass fractionator together with an “open architecture” chemical processing section in standard modular shipping containers which can each produce up to 2 million gallons of fuel per year. These modular fuel processors can be equipped with CoolPlanet Energy Systems' catalytic conversion processes and/or your own selection of dryers, separators, catalytic processes, etc.

Fast thermal/mechanical processing of biomass typically also produces a large quantity of neutral carbon since biomass has substantial excess carbon versus hydrogen when used to produce conventional petrochemical fuel components. The company is also developing long term sequestration options for this excess carbon.

See more and subscribe to NextBigFuture at 2012-08-05 01:40:55 Source: http://nextbigfuture.com/2012/08/solve-for-x-coolplanets-carbon-negative.html

Source: