| Online: | |

| Visits: | |

| Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

3D printed bacteria could be used to reduce graphene oxide

Researchers at Delft University have shown that placing certain types of bacteria on flat sheets of graphene oxide can turn it into a reduced version of the compound (rGO) by pulling oxygen atoms off the material as they metabolize. This turns the popular process of GO reduction, normally done with chemicals or high heat, into a much cheaper, more environmentally friendly process.

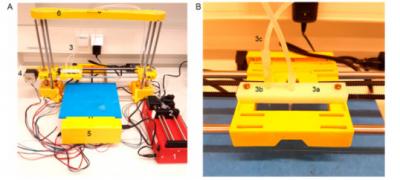

While the traditional method of reducing graphene with heat or chemicals is still more effective, the bacterial method could be very useful in the production of precise, small-scale graphene structures – such as those produced with a 3D printer. In this work, the researchers document how they modified a $300 CoLiDo 3D printer by replacing the extruder with a pipet tip and tubing system. “This alteration allows the liquid biological ink (‘bioink’) to be transported under ambient temperatures that are amenable to microbes, rather than the elevated temperatures that are applied to melt plastic filament,” the team explains.

Source: http://www.graphene-info.com/3d-printed-bacteria-could-be-used-reduce-graphene-oxide