| Online: | |

| Visits: | |

| Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

Buttoning up the bees

One task we needed to perform, before winter sank its teeth in too hard, was buttoning up the bees.

We had a spate of cold weather in November and I was reluctant to open the hive during that time since I didn’t want any of the heat escaping. Yet we also needed to check the status of the critters. So on a sunny and comparatively warm day (highs in the 40s), we suited up and opened the hive.

The top-most super was fairly empty, so we removed it entirely and tucked it in the barn. But the super underneath was heavy with honey, so we put the lid back on and left the rest of the hive alone, trusting in the bees’ instincts.

But we needed to insulate the hive. All the experienced beekeepers we spoke to said it’s best to wrap the hive to protect it from wind and cold.

So Don purchased a sheet of foam insulation that could withstand outside conditions (i.e. rain, snow, etc.).

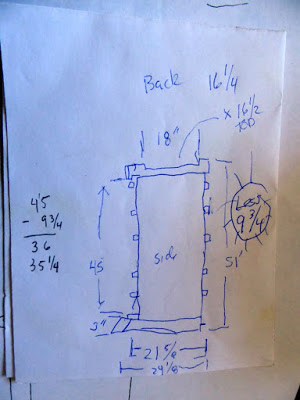

Then he took careful measurements of the hive…

…and sketched out what he needed to build a “box” of insulation.

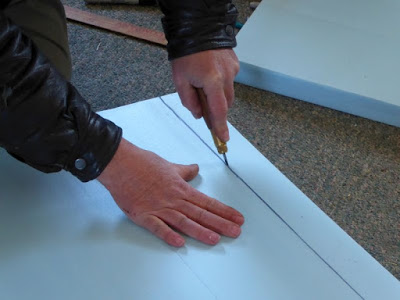

The foam was easy to cut.

He took the assorted cut pieces…

…and built a box. The corners are held together with very thin screws, reinforced with Gorilla-brand duct tape (which we hope will hold up to the elements).

Then we fitted the insulated sleeve around the hive.

We cut holes top and bottom where the bees have their regular access in and out of the hive (they have top and bottom “doors”).

Next step: a top.

Don scraped the ice off the lid of the hive…

…and fitted the foam top over the sleeve. He cut ventilation holes to allow moisture to escape (moisture build-up is one of the primary winter killers of hives). These holes will also allow bees outside access through their top door.

Gently, so as not to crush to foam, we ratcheted everything down with a ratchet strap.

Here’s the final result:

Hopefully this will help the ladies will make it through the winter!

Source: http://www.rural-revolution.com/2015/12/buttoning-up-bees.html