| Online: | |

| Visits: | |

| Stories: |

| Story Views | |

| Now: | |

| Last Hour: | |

| Last 24 Hours: | |

| Total: | |

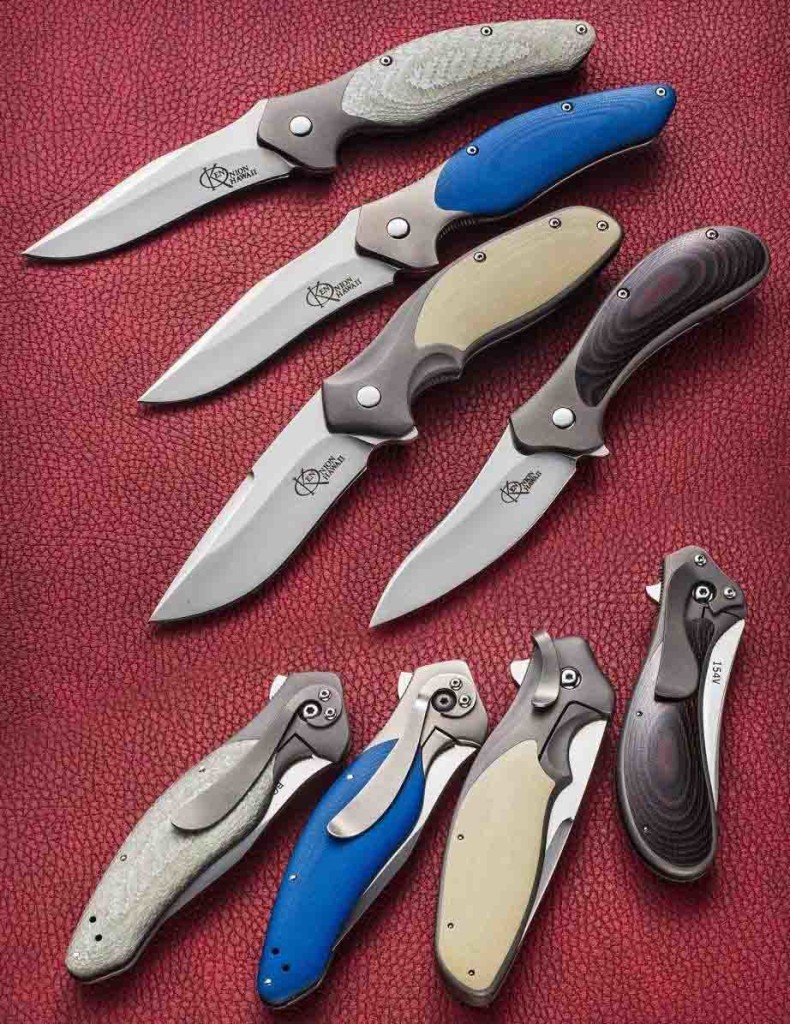

Conversation with Ken Onion–how to choose the right knife

TOP INVESTIGATIVE REPORTING AND ONLINE JOURNALISM AWARDS BEST BUSINESS AND GOVERNMENT REPORTING

by Rob Kay

In the first part of this series, master knife designer Ken Onion discussed the development of the assisted-opening knife that he created back in 1998. In developing this knife Mr. Onion was responsible for one of the most important advances in knife design in the last 100 years. It was a design that eventually required an act of the U.S. Congress and the signature of the President of the United States to make unmistakably legal.

In the next part of this series, conducted at his Kaneohe, Hawaii workshop, Ken provides tips on what to look for when purchasing a knife.

*****************

Q: So let’s talk about how to choose knife. Can you give me some tips?

A: Choose something you feel comfortable with. Something that suits your needs and applications. Something that’s not outside your comfort zone.

Q: What do you mean by ‘comfortable’?

A: There’s 20,000 knife designs out there. Everybody has their own particular application. Their own needs. Buy what makes you feel good. Buy what you like. Buy what suits your daily needs. If you’re not in the bushes all day hacking down lantana, you don’t need a big knife. I notice as I’ve gotten older, I tend to carry a smaller knife. When I was a younger man in the field I’d carry a bigger, beefier knife. Nowadays when I’ve got just about every kind of knife, I’ll carry a knife based on the kind of environment I’m going to be in.

Q: What’s the difference between a lower and higher end knife?

A: You get what you pay for. If you just want a beater because you’re afraid you’re going to lose it or don’t know how to sharpen it, get a cheapo knife. If you want a quality piece it’s going to cost. A lot of people look at a knife in a display cabinet and say they look similar. They ask “How come this one costs $29 and this one costs $200?” Well they can’t see the steel, they can’t see the hardware, they can’t see the precision in it. Good steel costs money. Knives made from cheap steel dull quickly. However some of the higher priced knives, the $200 knives they are made from CPM (Crucible Particle Metallurgy) alloys which is particulate metal, so they will hold an edge much longer. They won’t fail in an emergency situation. The heat treatment is right. The geometry is right. Fit and finish is proper, the hardware, the pivots, the precision are dialed in.

Q: What about choosing a kitchen knife? Any tips on that?

A: Same thing. Remember, if you’re buying a kitchen knife from a drugstore, you’re getting what you pay for. Chances are you’re getting a 420 carbon or lesser grade steel that won’t corrode, but won’t hold an edge either. The higher end kitchen knives cost more because they use a far superior blade steel. The difference is vast. I can buy some of those lesser blank alloys for 80 cents or a dollar a pound whereas a premium blade steel for a kitchen knife may cost me $25 or $30 a pound.

The more expensive steel is going to take twice as long to grind and twice and long to finish because it is a wear resistant powdered metal or nitrogen alloy. However it’s going to perform much better, it’s going to retain an edge much better than a cheaper knife. If you’re bit more discriminating, spend a little more money, at least on the knives you’re going to use every day. Get the best you can afford and the one that feels the best to you.

Q: What particular steels do you like best for wear and durability?

I’ve got a kitchen knife company and we have a nitrogen alloy that I’m really impressed with. It’s a BD1 alloy from a company called Carpenter in Reading, PA. There’s a small firm in Japan called Takefu and they have an alloy called SG2 that is my favorite blade steel for high performance kitchen knives. The downside to that steel is that it’s extremely expensive, something like $140 a pound and it’s very difficult to get. The difference with the nitrogen alloys is that by adding nitrogen to the chromium powders when they make the steel is that it transforms the chromium carbide into a ceramic carbide. Because the chromium carbide grain is so small, it stacks up on a cutting edge really well so that you can maintain super high edge retention much longer than a Vanadium enhanced alloy.

Q: Do you like ceramic knives for anything?

The problem with most ceramic knives is they are thick. You can’t get a thin cross section on a ceramic knife without making it very brittle. They are difficult to sharpen and anyone that says ceramic knives stay sharp forever hasn’t used them. It used to be they had ceramic knives that you’d drop on the floor and they would shatter into a hundred pieces now they are much tougher. They are using zirconium enhanced ceramics and it makes them more durable. But you’ll see they have a shallow grind and they are still thick which makes them more difficult to push through things as you’re cutting. They don’t slide through vegetable or meats like you want them to. The good thing about them is that they won’t tarnish. They are good for some applications.

Q: What new products do you have in the pipeline?

I’m coming up with a new category of knives that are smaller with tactical elements in them. I call them “Gentleman Tacticals” or “Genticals” for short. They have masculine lines and masculine textures to them. They would be a bit smaller than the typical tactical knife. It’s something you could carry in town.

Photos courtesy of On Target staff, Ken Onion and CRKT Knives.

Questions? Comments? Contact us at [email protected]

Use Facebook to Comment on this Post

Source: http://www.hawaiireporter.com/conversation-with-ken-onion-how-to-choose-the-right-knife/123